Here at GearLab, we love getting our hands on new power tools. When we decided to review impact drivers, we immediately got down to researching and brainstorming different ways that we could measure and test these products. Generally, we beat the heck out of them to find out which ones are suited for heavy-duty jobs and which ones are better for easy household tasks. Read below for an intensive description of our methods of assessment.

Speed

Impact drivers are primarily used to increase productivity on a project, so we opted to dedicate 35% of our total score to how quickly they perform their duties. We divided this metric into three sets of tests. Before running each speed test, we slightly drained each battery to avoid taking measurements during any initial power spikes after a full charge, which some of these tools are prone to show.

Plywood and Ledger Screws

For our initial speed assessment, we stacked enough sheets of plywood to accommodate the full length of a 3-⅝" ledger screw. We drove each screw the tiniest bit to eliminate any user error during the timing of the drive. We then performed five individual trials per impact driver and took an average of the measured times.

2x12 Boards and Ledger Screws

To acquire some numeric scores using an alternative wood, we employed some standard Douglas Fir 2x12 boards and the same ledger screws as the plywood test. The ends of each board seemed to be either especially tough or easy to drive into, so we chose not to time using those sections of wood. Also, because we couldn't see any knots on the lower boards, we decided to run seven trials rather than 5 to throw out any outliers before we took an average of the five trials that were closest together.

2x12 Boards and Lag Bolts

Because impact drivers are often used for larger fasteners, we wanted to see how they did driving lag bolts.

For this test, we used 2x12 boards for our testing medium as well as some ½" x 3" lags. Due to the large diameter of the bolts, we knew that holes needed to be predrilled — we used an 11/32" bit. The scores for this assessment were based on how fast each model could drive the bolt, then tiebreakers were decided by the removal time.

Torque

One of the greatest benefits of using an impact driver is they offer a ridiculous amount of torque. Because this is an important aspect to consider when buying one of these tools, we determined that this metric should account for 25% of the total score. To test torque, we considered two elements — how many foot-pounds each driver can achieve and how many they can break.

To test each model's twisting power, we welded grade 8 ¾" diameter bolts to a steel I-beam to have something we could really crank on. To determine how much torque the tools can produce, we first wore the batteries down a bit using ledger screws to avoid any power spikes when they're fresh. We then used each driver to tighten a washer and nut to the bolts for 5 seconds and conducted five trials per model. We checked the foot-pounds that each nut was tightened to with a torque wrench and took an average of the trials after dropping any outliers.

To test breaking power, we used the same I-beam setup, but this time we tightened the nuts to a set number of foot-pounds and then tried to loosen the nuts with each driver. Increasing by 25 foot-pounds at a time, we recorded the maximum torque that the tools could break up to 300 foot-pounds.

Convenience

Impact drivers may look alike at first glance, but they come with a wide array of features that can affect the overall convenience when using the tool. Some users may want a no-frills, straightforward model, while others may want all of the bells and whistles they can get — we dedicated 20% of the total score to convenience. For this metric, we conducted some quantitative analysis for elements such as size and weight. But in general, this metric was scored with a series of yes or no questions as to whether or not they have certain features, followed by a subjective judgment of how useful these features truly are.

Nearly all impact drivers have an LED light to help light up the fastener, but they are not all created equal. Some of the drivers include one dull bulb, while others come with a set of bright lights that illuminate the target of the driver. We noted which drivers have lights, how bright they are, and how long they stay lit.

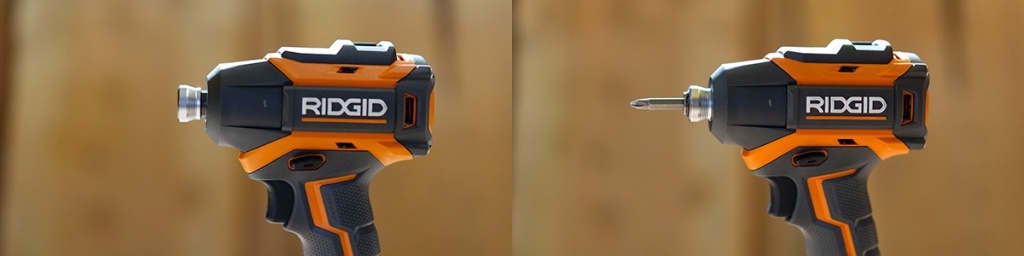

Each impact driver has a hex head socket for attaching various bits. Some of them are easier than others to operate, and we paid close attention to the differences.

The impact drivers in our review come with an array of features and accessories, including belt clips, bit holders, and magnets to hold bits and hardware — we paid close attention to the quality and functionality of these features and adjusted scores accordingly.

Battery

The battery life of a power tool can be very important to both professionals and DIYers. It's beyond frustrating to have your driver die when you're on a ladder, holding a piece of material that's ready to be fastened or 95% done with a certain job. The battery metric comprises 15% of each driver's score.

To test batteries, we drove 14 ledger screws, then the lag bolt in and out, and alternated between these two sets until the impact driver couldn't move any fasteners anymore.

To eliminate overheating issues, we cycled through the list of drivers between each 14 ledger screw/1 lag bolt set. Some models have RPM selector switches — we noted the different types, locations, and functionality of each design.

Noise

There's no way around it — impact drivers are loud. Although they may all seem to emit a similar amount of noise, we have found that this is not the case. Some of them produce bearable sound levels; others are outright painful. We have found enough variance from model to model to dedicate the final 5% of our total score to this metric. To measure noise, we used a sound pressure meter to associate a decibel level with each impact driver in our review. We took four readings per model while driving ledger screws into plywood as fast as possible, then took the average of the results.

Conclusion

Our goal at TechGearLab is to put products through the toughest, most in-depth testing process. Hopefully, this article has given you the confidence to make your purchasing decision based on our testing.