When it comes to woodworking, the precision and reliability of tools are paramount. Miter saws, especially, must offer accuracy and ease of use to meet the demands of meticulous crafters. Our extensive testing of miter saws aimed to provide clear insights into their performance. Here's how we put these essential tools through their paces and arrived at our conclusive ratings.

Ease of Use

To determine a miter saw's ease of use, we meticulously followed each manufacturer's steps for adjusting the miter and bevel settings. Calibration was key, requiring us to verify the accuracy of each angle adjustment. The process involved not only setting the miter angle to several predetermined points but also ensuring that the bevel could be adjusted with ease.

Changing the blade is an inevitable part of using a miter saw, so we changed the blade for each model, noting any difficulties or particularities. For operations like making dado joints, we tested the blade depth lock and evaluated the number of positive stops for quick adjustments.

To comprehensively evaluate the user experience, we used every feature provided by each product, ensuring a thorough understanding of each saw's capabilities.

Dust Collection

The dust collection test involved a controlled environment where we constructed a small enclosure and made 100 cuts through a 2x4. A vacuum attached to the hose port simulated a typical dust management system. We then did our best to clean off the saw. The collected dust was swept onto a paper and slid into a container to weigh the total.

This approach allowed us to quantify the collection efficiency of each miter saw, providing a clear comparison of their abilities to maintain a clean workspace.

Cut Capacity

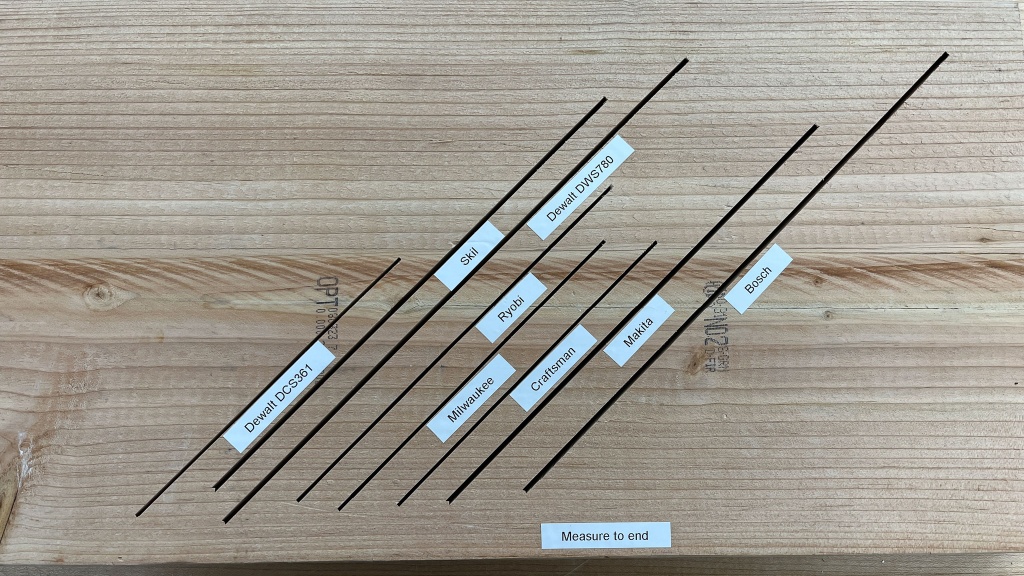

Our cut capacity test sought to identify the maximum size of dimensional lumber each miter saw could handle. This was tested by making cross-cuts at 45-degree miter angles across the face of the largest board possible. We also make cross-cuts and bevel cuts through different levels of thickness on 2x4s and 4x4s. The horizontal orientation allowed us to quantify the distance a product could travel and cut through. While cuts across the vertical plane allow us to establish the maximum thickness a saw can handle. For each saw, we identified the maximum cut distance on each plane.

Cutting Power and Speed

We evaluated cutting power and speed by challenging each saw to cut through a two-inch aluminum angle bracket with the sharp point facing upwards, thus cutting through both sides. Additionally, we tested the saws' ability to make consecutive cuts on 4x4 beams at a steady pace. These consecutive cuts simulated an 8x4.

To stress-test the saws, we cut through combined pieces of lumber at faster rates and monitored how well the blade maintained its speed when faced with increased surface area resistance. We also used a tachometer to record RPMs with a blade under no load, applying reflective tape to the blade to get accurate readings.

Precision and Accuracy

Precision and accuracy are crucial for a miter saw's performance. We measured the rotational angle of the saw blade set to 0 and 45 degrees using a Husky T-Bevel for miter angles and a Klein Digital Angle Gauge for bevel angles. These measurements were conducted out of the box and after testing. Out-of-the-box measurements give an idea of build quality and, after testing, provide insight into the necessary calibration frequency and resistance to drifting. Measurements that fell within this margin were recorded as accurate.

Additionally, we used a straight edge and feeler gauge to measure any gaps in the fence or table, noting that larger items might be more forgiving of minor inconsistencies than smaller items.

Through this rigorous testing process, we were able to assess each miter saw's strengths and weaknesses across multiple metrics. The data gathered from each test contributed to our final rating scores, ensuring that potential buyers have access to reliable and comprehensive information when selecting their next woodworking tool.